Purchasing your Elite machine

is just the beginning...

01652 681 883 enquiries@elitehogroastmachines.com

PRODUCTION |

The very best of British catering equipment manufacturing

Specialising in Stainless Steel and Aluminium fabrication for the food-processing industry, we have the perfect partner!

After extensive research we chose a manufacturer with the capability and capacity for producing our Elite machines, accessories and trailers to exacting standards and to meet the demands of our customers both here in the UK and on a worldwide basis

We are very proud to be working closely with a British engineering company based in the heart of the West Midlands

The factory itself is over 27000ft2 and employs 60 dedicated and skilled staff

The business has been built on world-class creative product design & development and is proud to have specialised in sheet metal & fabrication assembly for over 60 years

We are able to ensure that our Elite Roaster and our wide range of accessories are constantly evolving while maintaining the consistent high quality of our products

Our comprehensive range of efficient, profit-boosting accessories enables our customers to offer a more extensive menu offering to their diners

We have the experience and capacity to fulfil orders for a single roaster perfect for start-ups, up to large volume quantity orders for multi-national chains and franchises

You can rest assured, wherever you are in the world, we do deliver the goods!

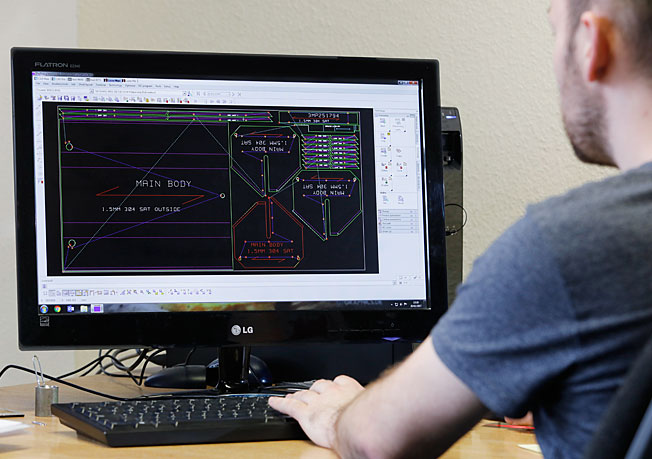

Computer Aided Design

Once the concept design is agreed the drawings are created using CAD

Our machine was drawn to ensure accuracy and consistency throughout the manufacturing process. Through continuous improvement and investment in cutting edge technology, efficient product manufacture and shop floor control is maximised

Super efficient material processing

Efficiencies throughout the factory ensure we are well equipped to maintain the high levels of service required by our customers

The factory’s Quality Management System monitors all the key areas of the process to ensure that the quality of our products exceeds our customers’ expectations while achieving timely delivery

The Quality Managament System has also been officially accredited to ISO 9001, providing extra peace of mind

Cutting Edge CNC Laser Profiling

Intelligent software ensures minimum material waste

Computer generated cutting forms are employed to minimise waste and maximise speed and efficiency during the cutting process

High speed, high power

Super accurate computer controlled laser cutting

The Trumpf 4kW flying optics laser cutting machine combines innovative technology with a high power laser

It offers versatile and flexible laser cutting and high speed processing. The use of Nitrogen gas gives clean, hygienically cut edges, critically important in the food sector

Component parts are successfully cut

The Elite Roaster component parts are collated and passed onto the next part of the process

Once the machine parts have been cut they are then removed by hand ready for assembly and folding to shape

Heavy duty in-house folding plant

Every part of the Elite roaster is made in-house to ensure quality and consistency

The bodies are efficiently precision folded to shape on the factory’s range of CNC Press Brakes (Folding Machines)

The folded bodies are batch processed

Once the profiles are folded they are then assembled in units of 10 – 15 at a time

The bodies are then passed onto the next stage, for welding and final assembly

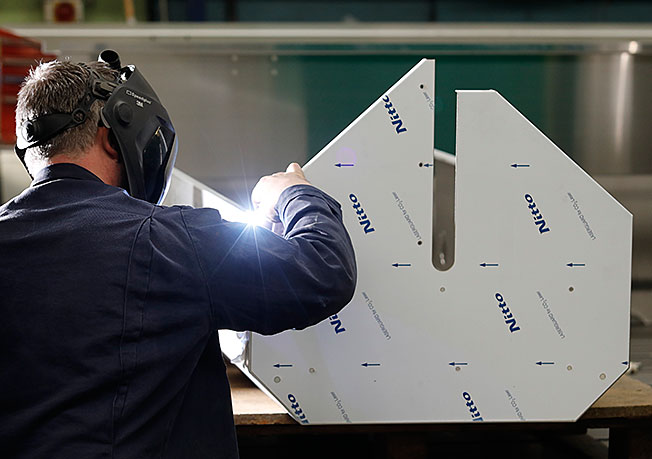

The Elite Roaster takes shape

Specialist Stainless Steel welding

Each and every machine is then welded by hand to ensure a precise and fantastic finish with consistency

Hand-crafted perfection in tool manufacture

Top quality assembly for a lifetime of use

All our spit-pole tools and accessories are top quality and precision crafted for longevity and reliability

The final finishing touches...

The last stage in the assembly process

Once the machine arrives in the Final Assembly department, the remaining parts are fitted and the gas components are rigorously tested for safety and is finally polished prior to dispatch to each customer

For our export customers we supply machines and accessories, fully crated and can arrange transportation, shipping and airfreight offering final delivery to clients anywhere in the world

Trailer manufacture and assembly

Lightweight yet truly durable trailer components

In the case of our trailers, the lid and all components are assembled by hand and every part is laser-profiled, welded and fitted in house

Fitting out the Elite Trailer

Once complete, the trailer is ready to pass to the sign-writers for graphics application

All our lids are powder-coated both internally and externally to match your corporate brand colour ready for our sign writers to apply graphics and the all-important crackling to each trailer body